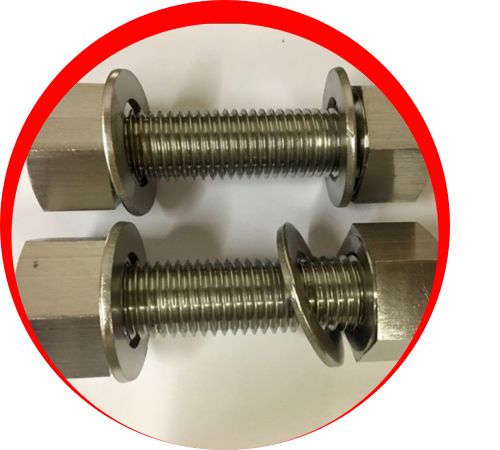

Hakan Nickel Alloys, a top-notch manufacturer and supplier located in Istanbul, Turkey, specializes in high-quality Inconel 625 Stud Bolts designed for demanding and critical applications. Known for their outstanding resistance to corrosion, oxidation, and extreme temperatures, these stud bolts ensure reliable fastening even in the toughest environments. Crafted with precision and rigorous quality control, Inconel 625 Stud Bolts from Hakan Nickel Alloys promise long-lasting durability, mechanical strength, and consistent performance, making them perfect for industries like aerospace, marine, chemical, and power generation.

Inconel 625 Stud Bolts are mainly made up of nickel (at least 58%), chromium (20–23%), and molybdenum (8–10%), along with iron, niobium, and trace elements that boost their strength and corrosion resistance. On the mechanical side, these bolts deliver a tensile strength between 830–1030 MPa, impressive yield strength, and excellent resistance to fatigue and creep. They maintain their shape and toughness across a broad temperature range, ensuring dependable performance in both cryogenic and high-heat conditions. Their remarkable corrosion resistance makes them ideal for harsh chemical and marine environments.

| Specification | ASTM F468, B166 / ASME SF468, SB166 |

|---|---|

| Size | M02 to M33, Custom Sizes |

| Length | 3 mm to 200 mm |

| Stud Bolt | UNF, BSW, BSF, METRIC, UNC, or as required |

| Standard | DIN 525, DIN 835, DIN 938, DIN 939, DIN 940, DIN 949-1, DIN 949-2, DIN 975, DIN 976, DIN 2509, BS 2693, BS 3692, BS 4439, IS 1862, IS 13178, ANSI/ASME B18.31.2, ANSI/ASME B16.5 |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Types | Stud Bolts, Fully Threaded Stud Bolts, Tap End Stud Bolts, Double End Stud Bolts, Stud Bolts with Reduced Shank, Reduced Shank, Flange Stud Bolts, Flange Bolting, Weld Studs |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production process | M24-M100: hot forging, M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Head drive of Stud Bolts | Six-Lobe, Phillips, Phillips/Slot, Slotted etc |

| Packing of Stud Bolts | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Surface Coating | Ptfe Coated Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

At Hakan Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Inconel 625 Stud Bolts in Istanbul, Turkey, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Turkey, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Inconel 625 Stud Bolts find extensive use in chemical and petrochemical plants for securing reactors, heat exchangers, and piping systems that come into contact with corrosive fluids. In the aerospace and marine sectors, they are utilized in turbines, exhaust systems, and seawater handling equipment where strong fastenings are essential. In the oil and gas industry, you’ll find them on offshore platforms, high-pressure pipelines, and subsea installations. Power generation facilities also rely on these bolts in boilers, nuclear reactors, and superheaters. With their exceptional strength, corrosion resistance, and thermal stability, Inconel 625 Stud Bolts are crucial for ensuring reliable and long-lasting fastening in challenging industrial settings.