Hakan Nickel Alloys, Istanbul, Turkey, is a well-established manufacturer and supplier of top-notch nickel-based alloy products such as Inconel 600 bars. Praised for their accuracy and compliance with international standards, Hakan Nickel Alloys supplies Inconel 600 bars for applications where they are to operate in demanding environments with high demands for corrosion resistance and mechanical strength. These bars are ideal for a broad spectrum of industrial applications where high-temperature and harsh chemical exposure is prevalent. The firm’s emphasis on quality guarantees consistent and long-lasting alloy solutions to rigorous engineering requirements globally.

The Inconel 600 bars are produced from a nickel-chromium alloy that has excellent resistance to oxidation, carburization, and corrosion in oxidizing and reducing environments. The alloy resists the loss of mechanical properties up to 1120°C and has excellent stress corrosion cracking and pitting resistance. The Inconel 600 has good weldability, creep resistance, and tensile strength, and is a general-purpose material applicable in various manufacturing processes and applications that involve thermal cycling and chemical exposure.

| Specification | ASTM B166 UNS N06600, AMS 5665 |

|---|---|

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square bar size | 4 to 100mm |

| Round bar size | Diameter: 3-~800mm |

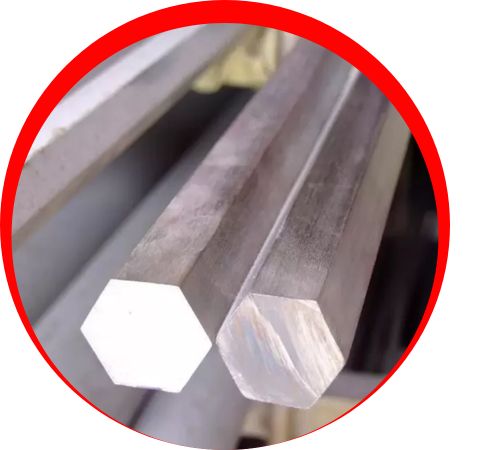

| Hex Bar size | 2-100mm A/F |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Billet Size | 1/2″ to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Condition | Hardened & tempered, annealed |

| Technique | 600 Inconel Cold Drawn, Hot Rolled, Forged Round Bar, Rod, Cold Rolled |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Cold Drawn, Bright, Sand Blasting Finished, Hot Rolled Pickled, Hairline, Polished |

| Processing | Bar cutting to 650mm |

| Form | Precision Ground Bar, Flat Bar, Square, Round, Half Round Bar, Rod, Rectangle, Hex (A/F), T-Bar, Channel Bar, Blocks, Round Rod, Threaded, Profiles, Billet, Ingot, I/H Bar, Forging, Rings, Hollow, Triangle etc. |

| Grade | Ni | Cr | Fe | C | Mn | S | Si | Cu |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 72.0 min | 14.0 – 17.0 | 6.0 – 10.0 | 0.15 max | 1.0 max | 0.015 max | 0.5 max | 0.5 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

At Hakan Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Inconel 600 Bars in Istanbul, Turkey, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Turkey, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Inconel 600 bars find extensive applications in chemical processing, aerospace, nuclear reactors, and power generation sectors. Typical uses are in heat exchangers, furnace parts, nuclear steam generators, and aerospace components. Their high-temperature corrosion resistance, mechanical properties, and strength make Inconel 600 bars a favored option for parts which need to function under harsh conditions reliably.