Home >Copper Nickel> Copper Nickel Slitting Coil

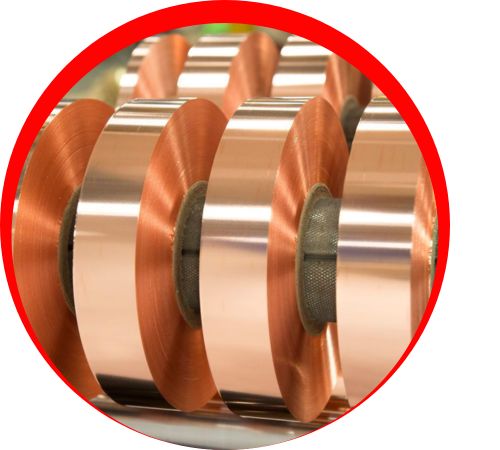

Hakan Nickel Alloys, located in Istanbul, Turkey, stands out as a premier manufacturer and supplier of top-notch metal products for markets around the globe. As a reliable Copper Nickel Slitting Coil Manufacturer in Da Nang, Vietnam, the company is dedicated to providing precision-engineered solutions that adhere to international standards. With state-of-the-art production facilities and rigorous quality control measures, Hakan Nickel Alloys guarantees that each slitting coil delivers exceptional consistency, durability, and performance. Their expertise covers a wide range of industries, supplying dependable materials that cater to demanding applications. The company’s commitment to innovation, timely delivery, and customer satisfaction has established it as a go-to partner for businesses worldwide.

The Copper Nickel Slitting Coils crafted by Hakan Nickel Alloys typically comprise 90% copper and 10% nickel, offering remarkable corrosion resistance along with high thermal and electrical conductivity. This material boasts impressive mechanical properties, including good tensile strength, ductility, and fatigue resistance. Its ability to endure harsh marine and chemical environments ensures long-lasting durability while remaining flexible enough for fabrication processes like slitting, bending, and forming. These coils also resist erosion and biofouling, promising a long service life even in challenging conditions, making them perfect for both industrial and specialized applications.

| Grades | Cu-Ni 90/10, Cu-Ni 70/30 |

| Thickness | 0.1mmThk To 3 mm Thk |

| Width | 3.2mm To 1500mm |

| Length | AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Cupro Nickel SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD, FULL HARD. |

| Form | Coil / Strip |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

At Hakan Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Copper Nickel Slitting Coil in Istanbul, Turkey, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Turkey, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Copper Nickel Slitting Coils find extensive use in marine, chemical, and power generation sectors due to their outstanding resistance to corrosion, seawater erosion, and biofouling. They are frequently utilized in heat exchangers, condenser tubes, pipelines, desalination plants, and components for shipbuilding. The slitting coil format allows for easy customization into specific widths and lengths, streamlining manufacturing processes. Moreover, their excellent thermal and electrical conductivity makes them ideal for electronic components and industrial machinery. Industries that require reliable materials can count on these coils to meet their needs effectively.