Home > Copper Nickel > Copper Nickel 90/10 Flanges

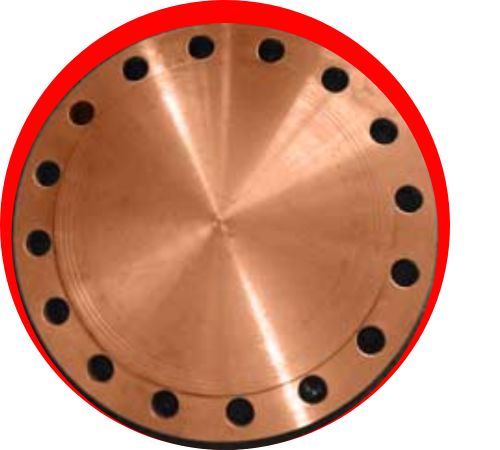

Hakan Nickel Alloys, located in Istanbul, Turkey, stands out as a top-notch manufacturer and supplier, particularly known for its high-quality Copper Nickel 90/10 flanges. With a strong commitment to precision engineering and ensuring customer satisfaction, this company delivers dependable solutions across various sectors, including marine, petrochemical, and power generation. Hakan Nickel Alloys boasts an impressive selection of flange types, such as weld neck, slip-on, blind, and socket weld, all crafted to meet international standards. Renowned for its technical know-how and efficient logistics, the company caters to clients worldwide, offering competitive pricing, prompt deliveries, and a dedication to exceptional product performance.

Copper Nickel 90/10 flanges are made up of roughly 90% copper and 10% nickel, with trace amounts of iron and manganese to boost their strength and resistance to corrosion. This alloy is particularly effective against seawater corrosion and stress corrosion cracking, making it ideal for marine settings. In terms of mechanical properties, these flanges typically exhibit a tensile strength ranging from 275 to 350 MPa, a yield strength around 120 MPa, and an elongation of about 30%. They hold up well under high pressure and extreme temperatures, making them perfect for demanding industrial applications that require both durability and reliability.

| Specification List | Copper Nickel 90/10 Flanges |

|---|---|

| Face Type | Raised Face (RF) Flat Face (FF) Ring Type Joint (RTJ) |

| Types | Threaded/ Socket Weld/ Blind/ Slip On/ Reducing/ Weld Neck/ Lap Joint |

| Size Range | NPS 1⁄₂” Inch To NPS 48” Inch |

| Thickness | SCH 5S To SCH 180. |

| Chemical Chart | Cu (88.6 min.), Ni (9-11 max), Mn (1.0 max), Pb (0.05 max) etc. |

| Related Specifications | CN102 C70600 C70610 CW352H DEF STAN 02-879 Annex C DEF STAN 02-779 NES 779 BS2870 BS2874 ASTM B151 EN 12163 2.0872 NF A51-115 CuNi10Fe1Mn |

| Pressure Class | Class 150 To Class 2500. |

| Standard & Dimensions | P235GH/ API/ EN 1092-2/ ISO/ PN/ DIN 2561/ DIN 2501/ JIS/ DIN 2527/ EN 1092-1/ |

| Forging Methods | Rolling/ Casting/ Cutting/ Forging |

| Grade | Fe | Zn | Cu | Mn | Pb | Ni |

| Copper Nickel 90/10 Flanges | 1.8 (max.) | 1 (max.) | 88.6 (min.) | 1.0 (max.) | .05 (max.) | 9-11 (max.) |

| Element | Tensile Strength | Density | Yield Strength (0.2%Offset) | Elongation | Melting Point |

| Copper Nickel 90/10 Flanges | 50000 psi | 0.323 lb/in3 at 68 F | 20000 psi | 30 % | 2260 F |

These Copper Nickel 90/10 flanges are a popular choice in the marine and offshore industries, thanks to their outstanding resistance to saltwater corrosion and biofouling. They’re commonly used in shipbuilding for systems like seawater cooling, ballast water, firefighting, and bilge lines. Additionally, these flanges find applications in desalination plants, heat exchangers, and offshore oil and gas operations. In the realms of power generation and chemical processing, their ability to endure corrosive fluids ensures they perform reliably over time. Their robust nature, paired with low maintenance needs, makes them an excellent option for tough and corrosive environments.

Contact us to get a quick quote for your requirement.

Copper Nickel 90/10 flanges are widely used in the marine and industrial industries, including shipbuilding, offshore oil and gas platforms and desalination plants, as they have excellent seawater corrosion resistance though connect pipes, valves and pumps to systems exposed to environmental corrosion They needed. In addition, these flanges are used in heat exchangers, condensers and cooling systems where durability and biofouling resistance are important Their strength and reliability make them suitable for use in severe and harsh conditions.