Home > Copper Nickel > Copper Nickel 90/10 Bars

Hakan Nickel Alloys, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of Copper Nickel 90/10 Bars. These bars are known for their durability and resistance to corrosion, making them perfect for marine, offshore, and industrial uses. They excel in saltwater environments and are crafted to meet international standards with precise dimensional tolerances. Hakan Nickel Alloys is committed to delivering high-quality and consistent Copper Nickel 90/10 Bars, which are ideal for structural components, marine hardware, and fluid handling systems. Their expertise and dependable supply chain make them a go-to source for copper-nickel materials in various industries worldwide.

Copper Nickel 90/10 Bars consist of about 90% copper and 10% nickel, with small amounts of iron and manganese added to enhance strength and corrosion resistance. These bars typically have moderate tensile strength, ranging from 275 to 360 MPa, and they offer outstanding resistance to seawater corrosion, biofouling, and hydrogen embrittlement. The alloy is thermally stable, highly ductile, and easy to machine and weld. It performs exceptionally well in saline environments, resisting pitting and stress corrosion cracking. Additionally, Copper Nickel 90/10 Bars are non-magnetic, making them suitable for sensitive instrumentation and marine applications where reliable performance is crucial.

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

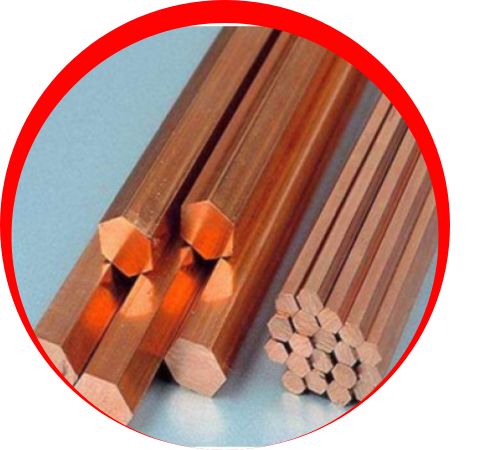

| Round bar size | Diameter: 3-~800mm |

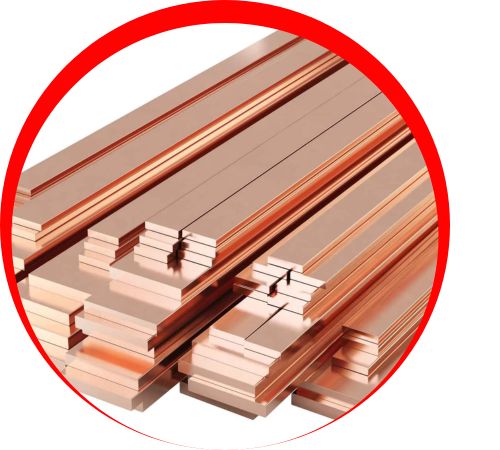

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Dimensions | Diameter / Height: |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Stainless Steel Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

| Grade | Element | |||||||

|---|---|---|---|---|---|---|---|---|

| Cu | 88.7 | |||||||

| Fe | 1.3 | |||||||

| Ni | 10.0 | |||||||

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 303-414 MPa | 43900-60000 psi |

| Tensile strength, yield (depending on temper) | 110-393 MPa | 16000-57000 psi |

| Elongation at break (in 254 mm) | 42.00% | 42.00% |

| Machinability (UNS C36000 (free-cutting brass) = 100%) | 20% | 20% |

| Shear modulus | 52.0 GPa | 7540 ksi |

| Poisson’s ratio | 0.34 | 0.34 |

| Elastic modulus | 140 GPa | 20300 ksi |

At Hakan Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Copper Nickel 90/10 Bars in Istanbul, Turkey, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Turkey, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Copper Nickel 90/10 Bars find extensive use in shipbuilding, offshore structures, seawater piping systems, condenser components, and marine heat exchangers. Their corrosion resistance makes them ideal for ballast systems, fire mains, and cooling lines that are exposed to saltwater or brine. They are also utilized in power plants, desalination systems, and various chemical processing applications.